| Planner_Termintreue |

More reliability, less trouble

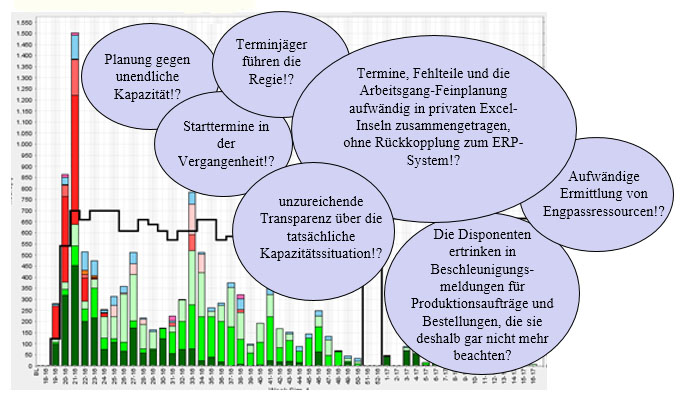

Does the following sound familiar?

- Planning against an infinite capacity?

- Commencement date in the past?

- Progress controllers rule the day?

- Appointments, missing parts, machine allocation or occupancy are collected in isolated Excel lists without any feedback to the ERP system?

- Inadequate transparency regarding the actual capacity?

- Elaborate calculations of any bottlenecks regarding the resources?

- The dispatchers are inundated with acceleration messages/requests? (addition in the diagramme: for production and purchase orders, which they thus start to ignore)

The conventional MRP (material requirement planning) systems dispatch primary requirements by starting from the due-date/requirement-date and then calculate backwards from this, level by level.

Provided the primary requirements (sales orders, forecasts) themselves do not already have feasible due dates, a quantity scheduling framework will arise, with past dates and an arbitrary capacity overload.

It thus becomes difficult for the end-user/operator to determin whether the desired deadline for a customer's order or the made-to-stock production is feasible.

This leaves many unresolved questions:

- When can we deliver?

- Will we deliver on time?

- Where are the bottlenecks in the order?

- What do we need to do first?

That's why you need an APS!!

The only remedy/solution is an APS planner (advanced planning system)

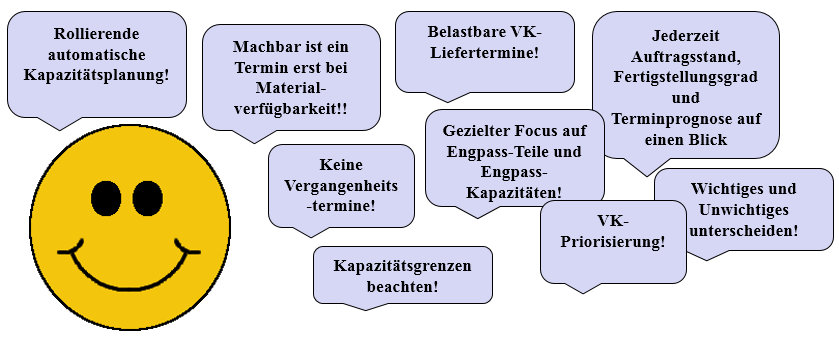

The outcome would be:

- No more past due-date scheduling.

- Capacity bottlenecks re-scheduled

- Availability of material checked

- Priorities taken into account

- Bottlenecks pointed out transparently

- Feasible production deadlines

A deadline is feasible when both the material and the capacity are available. Thus the important aspects take precedence over the less important!

Ascon plug-in converts LN to APS

LN-Standard also belongs to the conventional ERP systems, which excel in backwards planning. In contrast our fully compatible add-on ascon-planner (as an APS in the Infor/LN environment) calculates all dealine dates backwards and forwards simultaneously in several stages against possible limited capacities and material. This results in a comparison between the desired date and a feasible date.

Priorities are taken into account, feasible production sequences are proposed and bottlenecks are pointed out transparently.

With a simple click the sales department can determine the feasible date directly when entering the sales order, which will have been checked against capacity and material availability in several stages.