| Reservationssystem |

| Planner_Chain |

Mit LN und dem ascon-Planner die interne Supply Chain tunen

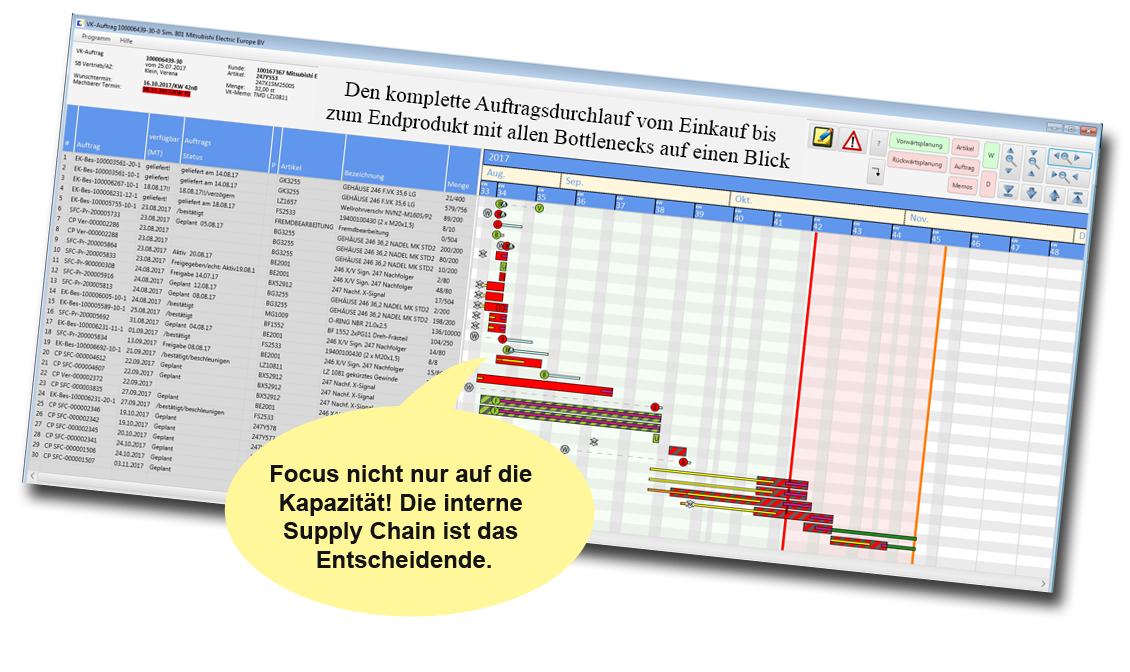

Collective order network as a Gantt-Chart

In the form of a Gantt-Chart the collective order network showns the remaining oder processing until the final completion of the product including all the bottlenecks. In the chart tooltip the cursor activates the various resource data including information on the purchase order, production order, production proposals and much more ...

-

production order/production proposal on time or too late. The tooltip shows the order details

production order/production proposal on time or too late. The tooltip shows the order details

-

Capacity bottleneck with a delayed commencement of operations. The tooltip shows the relevant machine or department.

Capacity bottleneck with a delayed commencement of operations. The tooltip shows the relevant machine or department.

-

Remaining term of a production order

Remaining term of a production order

-

Mouse: shows a memo text regarding a production order or puchasing order (“not possible earlier“)

Mouse: shows a memo text regarding a production order or puchasing order (“not possible earlier“)

-

construction site sign shows that a work plan/ production schedule is still missing or that a signal code has been set

construction site sign shows that a work plan/ production schedule is still missing or that a signal code has been set

A Gantt-chart is directly accessible from various sessions. e.g. A sales order item is displayed with the info “ will probably be completed 5 days too late“. A mouse click on this line will open the Gantt-chart which transparently shows the bottlenecks. Thus one knows what to do timeously and maybe will still be able to salvage the order!!

| Block_chain_01 |

| Distribution/order control centre | |

|

Determining the feasible deadlines and bottlenecks directly when accepting orders.

|

| Block_chain_02 |

| Purchasing and procurement | |

Specific indications regarding changes in demand, differentiating between direct/indirect demands for customer orders and stock orders.

|

| Block_chain_03 |

| AV = Dependent variables / production control | |

|

Support for realistic capacity planning, Proposals for sequencing, Urgency and backlog processing, Monitoring instruments for on-time production, Notification of impending material and capacity bottlenecks – All this information will be available long before it becomes reality!! |

| Block_chain_04 |

| Automatic rolling resource planning | |

|

After the mrp (material requirements planning) check, the ascon-planner automatically revises the internal schedules/appointments. It plans rolling limited capacities and re-schedules operations if the delivery by the supplier is expected to be late. It checks all collective order networks and reports when it is foreseeable that a sales order will not be completed on time.

|