| Reservationssystem |

| Planner_Kapazität |

Capacity

Capacity limitation

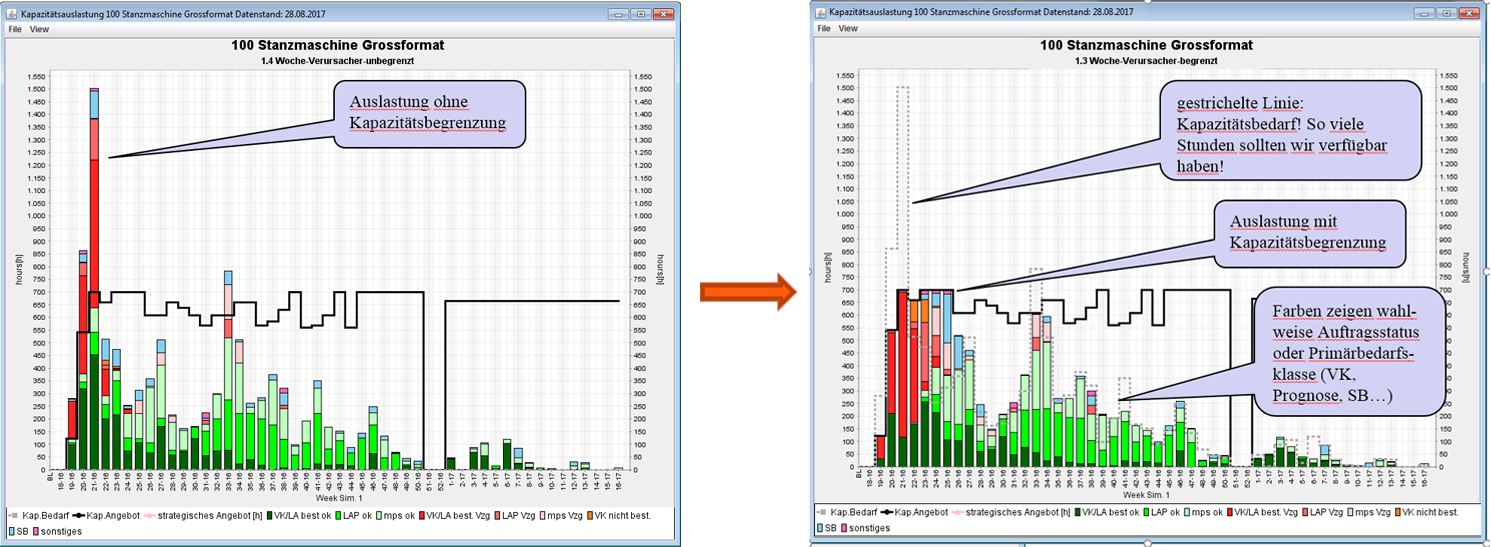

The tool does most of the work on its own. The knowledgable operator/end-user only intervenes to correct. For each machine or department you have the choice of:

A limited capacity or an unlimited capacity. You define such settings in the master data of the add-on.

The ascon planner then automatically takes into account the limitation in its planning run. You can even run different simulations parallel in the same instalation with different planning settings. e.g. “What effect would a 3rd shift in department 4711 have?”

Unlimited capacityUnlimited capacity in the planner, nevertheless, eliminates all past dates. Past is Past!!

|

>90% After a certain time the users of the ascon planer achieve well over 90% internal delivery reliability. Of course the tool alone does not achieve this, the organisation must also be trimmed. |

Limited capacityYou decide which capacity will be limited. When the capacity is limited, then less important operations are automatically postponed, should this be required: The dotted lines in the chart denote the actual capacity requirements. |

| Block_Kapazitaet |

The result of the automated continuous and rolling planning is a multi-tiered coordinated daily- or shift-sequence proposal for the execution of the various work steps. The planning can either be printed as a processing list or transferred to the PDA (production data acquisition) or displayed on the screen, where it can be worked on and corrected manually.